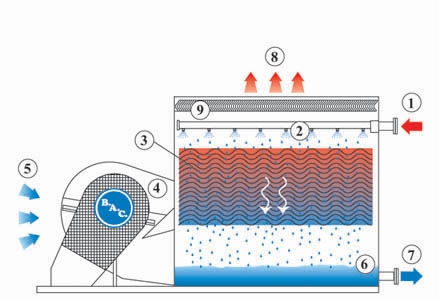

Warm process water (1) from the heat source enters the spray system (2) at the top of the cooling tower where it is distributed over the fill or heat transfer media (3). At the same time the centrifugal fan (4) blows ambient air (5) upwards through the tower. While the warm process water contacts the cold air the latter heats up and part of the process water is evaporated which removes the heat from the remaining water. The tower sump (6) or basin collects the cooled water (7) after which it returns to the heat source of the process. The warm saturated air (8) leaves the tower through the drift eliminators (9), which remove water droplets from the air.

Warm process water (1) from the heat source enters the spray system (2) at the top of the cooling tower where it is distributed over the fill or heat transfer media (3). At the same time the centrifugal fan (4) blows ambient air (5) upwards through the tower. While the warm process water contacts the cold air the latter heats up and part of the process water is evaporated which removes the heat from the remaining water. The tower sump (6) or basin collects the cooled water (7) after which it returns to the heat source of the process. The warm saturated air (8) leaves the tower through the drift eliminators (9), which remove water droplets from the air.

Want to use the VTL-E cooling tower to cool your proces water? Contact your local BAC representative for more information.