Key benefits

- Unmatched energy savings with less than 2 years payback.

- Low maintenance and easy inspection, 25% reduction in annual maintenance costs.

- Extreme low sound levels matching centrifugal fan units with attenuation.

Unmatched energy saving

- Evaporative cooling for system-wide energy saving at lower operating temperatures.

- Axial fan uses half the energy of similar centrifugal fan units.

- Save pump kW! Less pump head for this gravity water distribution system. In periods of reduced load, weir dams close off partly the hot water basin saving pump energy.

- BACross fill – factory-configured for maximum water/air contact and low air pressure drop for optimal cooling tower efficiency with limited energy consumption.

- High efficiency fan motors

- Multiple fan motor system covers independent fan motor and drive assembly per fan. In case of fan failure, the other fan(s) can still operate.

- XES1500E line with smaller motors to reduce electricity consumption for the same cooling capacity.

Low maintenance and easy inspection

- Unrivalled safe and comfortable access. Inspect and maintain the tower while standing and without crawling.

- The S1500E has a spacious plenum (internal area) and easy inspection/maintenance access.

- Access via large hinged door. With optional internal walkway: no basin draining needed for unit interior or fill pack inspection.

- Inspection of water distribution system (hot water basin and nozzles) possible outside the unit, during operation.

- Distribution basin covers prevent debris collecting in the unit.

- You can inspect and clean easily the core of the BACross fill sheet by sheet without dismantling. BACross design reduces fouling. Optional telescopic fill supports for easy replacement of the sheets.

- The fill includes integrated drift eliminators.

- Self-cleaning cold water basin and fill above sloped basin to flush out dirt and debris.

- Fans are easily accessible from the in- and outside

- Optionalclean out port helps remove silt and sludge from the cooling tower basin.

- Removable suction strainer anti-vortex hood.

- Optional sump sweeper piping prevents sediment collecting in the cold water basin.

- Various corrosion-resistant materials, including the Baltiplus 810TM coating for guaranteed long service life.

- Optional motor removal davit for easy motor replacement.

Extreme low sound levels

- A choice of various fan types such as low noise axial fans and Whisper Quiet fans for minimal surrounding noise.

- BACross fill smoothly guides the water all the way into the basin without water splash noise.

- Single-side air inlet, and a quieter tower rear for more noise-sensitive areas.

- Try our XES1500E line with smaller motors for extremely low noise levels.

- Factory designed, tested and rated sound attenuation is available on air inlet to cut operation noise even further.

Superb hygiene control

- Proper hygiene inspection without unit shut-down.

- Easy-clean and easy-inspect S1500E towers reduce hygiene risks from bacteria (eg Legionella) or biofilm inside.

- Self-cleaning cold water basin and fill above sloped basin to flush out dirt and debris.

- BACross fill for reduced fouling and easy sheet by sheet cleaning without dismantling.

- The fill includes integrated drift eliminators.

- Combined inlet shields block sunlight to prevent biological growth in the tower, filter the air and stop water splashing outside.

- Optional distribution basin covers prevent debris collecting in the unit.

- Optional clean out port helps remove silt and sludge from the cooling tower basin.

- Optional sump sweeper piping prevents sediment collecting in the cold water basin.

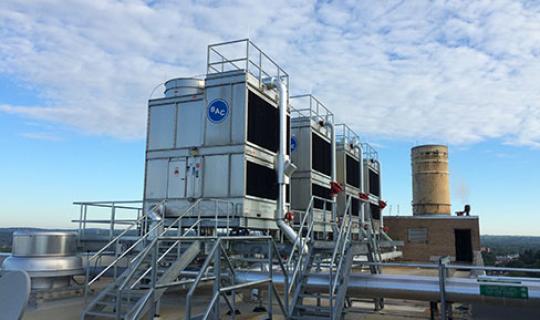

Ideal replacement unit

- Single side air inlet and discharge, fits in most enclosures.

- S1500E are ideal replacement units. Small fan motors and low spray pressure allow re-use of existing electrical cabinet.

- S1500E cooling towers are factory-built and shipped in 1 or 2 sections to reduce the overall size and weight, allowing easy on-site section assembly with smaller crane.

Year round reliable operation

- Optimal unit condition thanks to inspection during operation.

- The thermal performance of S1500E cooling towers is tested and CTI-certified.

- Proven freeze free winter operation.

- Multiple fan motor system covers independent fan motor and drive assembly per fan. In case of fan failure, the other fan(s) can still operate.

- Various corrosion-resistant materials, including the BaltiPlus 810TM coating for guaranteed long service life.

- The thermal performance of S1500E cooling towers is CTI-certified.

Interested in the S1500E cooling tower for cooling your process water? Contact your local BAC representative.