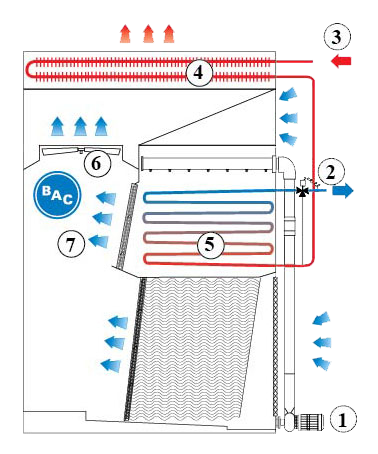

Dry operation

The spray water pump (1) is turned off and the modulating flow control valve (3-way valve) (2) remains fully open. The warm process fluid (3) flows both through the finned discharge coil (4) and the prime surface coil (5).

An axial fan (6) draws the ambient air (7) over the coil and the heat is rejected from the fluid inside the coil. In this mode neither water consumption nor plume occurs.

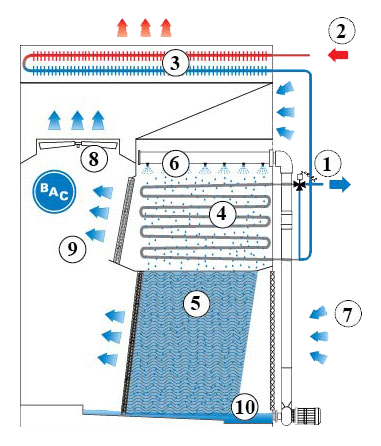

Adiabatic operation

The flow control valve (3-way valve) (1) lets the warm process fluid (2) flow through the finned discharge coil (3), by-passing the wet prime surface coil (4). The prime surface coil and the fill pack (5) are wetted by the spray water (6) but there is no water evaporation for heat rejection purposes. Some water will however evaporate. This will humidify the incoming ambient air (7) that is blown over the finned discharge coil by an axial fan (8). This saturated air (9) has a better cooling capacity to cool down the process fluid in the finned coil. The spray water drops into a sloping basin or sump (10). A pump recirculates the water to the spray system. Visible plume and water consumption are greatly reduced while the design fluid outlet temperature is kept.

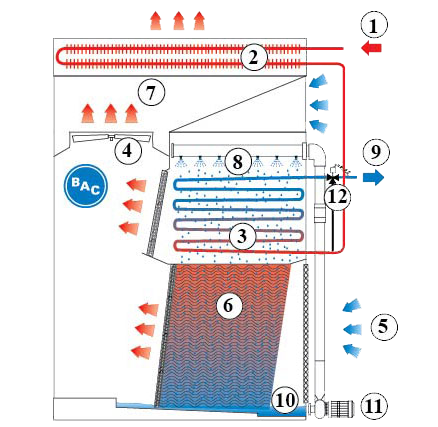

Wet-dry operation

The warm process fluid (1) flows both through the finned discharge coil (2) and the prime surface coil (3). An axial fan (4) draws the air (5) over both coils and fill pack (6). At the top where the warm fluid enters the tower, the discharge air (7) is saturated and pre-cools already the fluid. Then a next heat transfer process occurs in the prime surface coil which is wetted by the spray system (8). The cooled fluid exits (9) the tower. The spray water flows further over a fill pack, improving the heat transfer process by sub-cooling the spray water. The water is collected in a sloping basin (10) and a pump (11) recirculates the cooled water again over the prime surface coil. When there is less heat load or the ambient temperature drops, the modulating valve (12) will control the flow through the prime surface coil in a way that the design fluid outlet temperature is kept and water is saved. Plume is also minimized because there is less evaporated water and the discharge air is heated with the dry finned coil.

Want to use the HXI hybrid cooling tower to cool your process fluid? Contact your local BAC representative for more information.