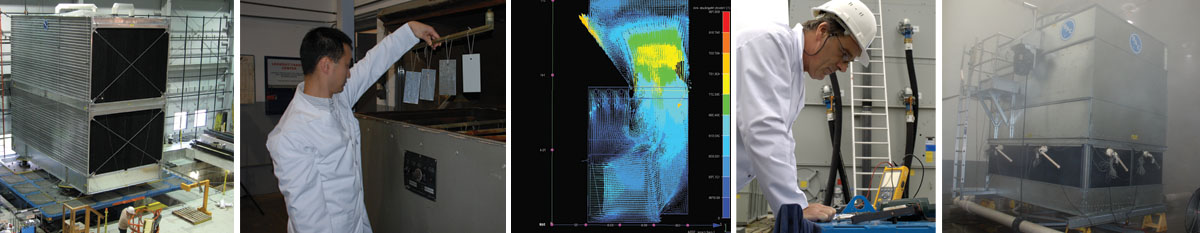

Baltimore Aircoil's Research and Development Centre in Baltimore (USA) is the industry leader, with a dedicated facility for testing and developing evaporative and adiabatic cooling equipment and ice thermal storage units. From small prototypes to full-size equipment, its large test chambers can simulate the whole range of environmental and system operating conditions.

State-of-the-art testing

Whatever the task, our experts use computer data acquisition systems and advanced fluid dynamic simulations to find a range of possible solutions. R&D experts test various combinations of fill, airflow rates, fans and motor sizes combined with various construction before the market launch of new products. In developing new materials and components, the R&D team measures dynamic and static stress and performs hydraulic and wind tunnel tests. To develop new corrosion protection systems, tests involve exposure to salt spray, impact erosion, ultraviolet and thermal shock.

In R&D, we strive for ever-improving technology and solutions with:

- higher performance efficiency

- easier installation

- easier maintenance

- longer service life

- minimum ecological impact,

and that meet the demands of customers and applications.

An innovative pioneer

Our efforts have earned us many European product innovations and patents, recognized as milestones and benchmarks.

- 1968: V-line cooling towers and condensers

- 1971: Ejector cooling towers

- 1978: VX-line cooling towers and condensers

- 1980: FXT cooling towers

- 1981: Baltibond Corrosion Protection System

- 1982: Ice thermal storage units

- 1984: Sound attenuation systems

- 1988: VL-line cooling towers and condensers

- 1989: Series 3000 cooling towers

- 1992: IMT fiberglass industrial cooling towers

- 1995: Series 1500 cooling towers and condensers (combined flow)

- 1999: Hybrid cooling tower HXI; Balticare cooling tower and condenser services

- 2005: Trillium Series adiabatic coolers, HFL hybrid cooling towers, HXC hybrid condensers, RCT fiberglass cooling towers

- 2006: Trillium Series adiabatic condensers

- 2010: Helios Series PE cooling towers and condensers; SpartiumCoolers

- 2011: FXVE cooling towers and CXVE condensers

- 2012: The new generation Baltibond hybrid coating

- 2014: VT0/1, (XE)1500E, (XE)S3000E open cooling towers; CO2 TrilliumSeries condenser

- 2015: PFI closed circuit cooling towers; Eurovent-CTI certified FXVS, FXVT and PFI

Proof indeed that BAC is continuously improving. Our proven expertise is key to our solid reputation as a reliable, respected business partner providing perfect solutions to customer cooling needs.

Want to know more about our product innovations? Contact your local BAC representative for more details of each innovative technology.